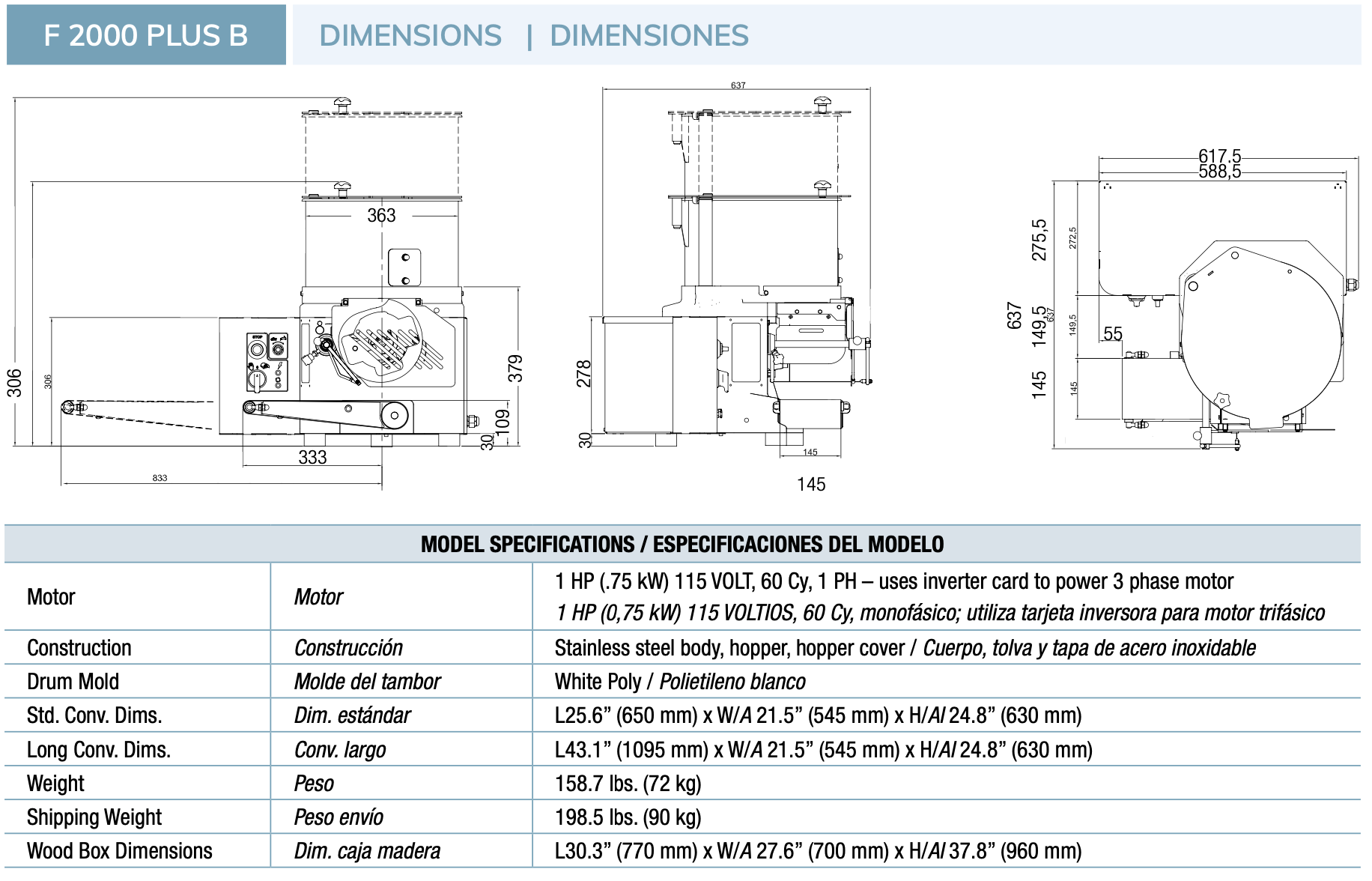

STANDARD EQUIPMENT

• Heavy – duty machine , designed for production of a wide variety of meat and food products

• Compact, reliable and versatile has a small foot print

• Variable speed – drum & conveyor synchronized

• High productivity : can deliver up to 3,600 cycles per hour

• 1 HP (.75 Kw)

• Stainless Steel Feed Paddle

• Manual Wire Cleaner for drum

• Standard conveyor belt 15 ⅜”(390.5 mm)

• Hopper capacity – 25 Liters (Approximately 35 pounds.)

• Foot switch – start/stops former and conveyor

• Cleaning Tilt Stand

• No specific dismantling tools

• Ease of cleaning

• Certifications: N.S.F., E.T.L.

Different drum shapes available ( not included in the standard equipment ) :

• Standard round shapes of different diameters – maximum product diameter of the 5.12”(130mm)

• Double/triple shapes as oval, rectangular , square

• Special shapes such as : fish, cutlet, heart, chicken nuggets, tree, pork chop , etc

The mold die in the drum allows the operator to select product weights by changing the mold die depth (thickness) up to 1¼” (32 mm).

OPTIONAL

• Auto – feed patty paper attachment

• Paper sizes : accepts up to 5½”(135mm) square paper or the smaller 114mm, one package includes 13.500 sheets

• Longer Conveyor Belt Assembly 35⅜” (898.5 mm)

• Extended Hopper Capacity – 40 Liters (56 lbs.)

• Pneumatic Wire Cleaner for Drum

• Support table with wheels

DETAILS